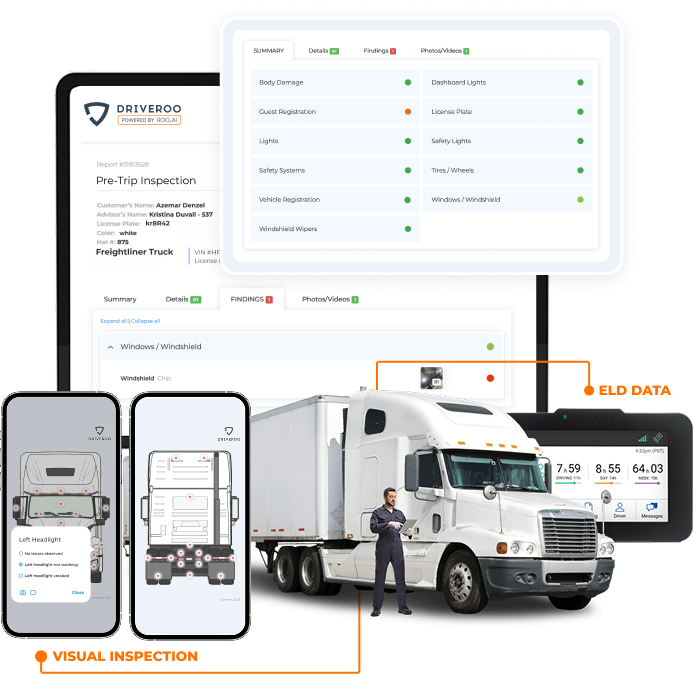

Electronic Logging Devices (ELDs) have transformed the transportation industry and equipment fleets by ensuring compliance with Hours of Service (HOS) regulations and providing real-time engine diagnostics. With the advent of predictive maintenance and AI, the rich data from ELDs stands to further improve the operational efficiency of equipment and vehicle fleets. However, an ELD alone does not guarantee a vehicle is safe, roadworthy or ready to perform its function. Physical defects such as physical damage, worn-out tires, broken lights, or fluid leaks cannot be detected by an ELD, making a thorough pre-operation inspection essential.

A proper Driver Vehicle Inspection Report (DVIR) or pre-operational inspection goes beyond electronic monitoring, ensuring that equipment is safe, reliable, and ready for the task at hand. This eBook explores why visual pre-trip inspections remain crucial, how they prevent costly breakdowns, and how combining them with ELD data provides the most complete picture of vehicle health.

ELDs Do Not Detect All Mechanical Issues

ELDs are powerful tools, but they have limitations. They can track engine performance, alert drivers to diagnostic trouble codes (DTCs), and monitor fuel efficiency. However, they do not detect external mechanical issues, including:

- Tire Wear & Pressure: An ELD will not indicate if a tire is underinflated, balding, or developing sidewall cracks.

- Lights & Signals: A broken taillight or turn signal won’t trigger an ELD alert, but it could lead to fines or safety hazards.

- Fluid Leaks: Coolant, oil, hydraulic or brake components fluid leaks are visible during a walkaround but not immediately visible to an ELD.

- Physical & Structural Issues: A damaged frame, dented shovel, missing safety guards or worn-out suspension component can be dangerous but won’t be flagged electronically.

Without a thorough pre-trip visual inspection, these issues can go unnoticed until they cause operational issues, a failed roadside inspection, or an accident.

Visual Inspections Prevent Costly Breakdowns

Breakdowns result in lost time, expensive job-site or roadside repairs, and potential safety hazards. A detailed pre-trip inspection allows operators to spot small issues before they escalate.

- A minor tire pressure issue detected in a walkaround can be corrected before it leads to a dangerous blowout.

- A small fluid leak identified during inspection can be repaired before it causes engine overheating.

- A loose hose or missing lug nut can be addressed before the vehicle is put in motion, reducing risk and repair costs.

Ensuring Operator Accountability

A pre-operations inspection is only effective if drivers actually perform it diligently by walking around the equipment. Relying solely on checklists sitting next to an ELD without verification can lead to rushed or incomplete inspections. Companies can encourage accountability by:

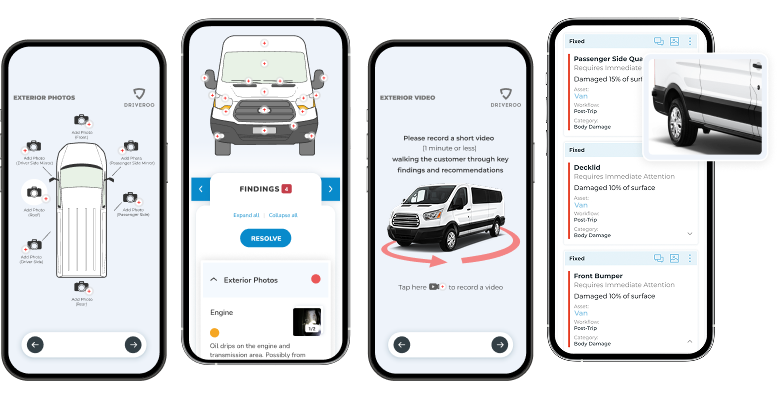

- Requiring Photo/Video Documentation: Asking drivers to submit images of critical components ensures inspections are conducted properly.

- Using Digital Inspection Tools: Mobile apps allow drivers to check off items while making comments and taking pictures, making it easy to verify the process.

- Incentivizing Thorough Inspections: Rewarding drivers for consistent, high-quality inspections encourages compliance.

When operators take ownership of inspections, the entire fleet benefits from improved safety and reliability.

Images & Videos Help Maintenance Teams Prioritize Repairs

An electronic alert alone may not provide enough detail for maintenance teams to quickly assess a problem. By integrating photo and video documentation into the DVIR process, equipment managers can:

- Prioritize Critical Repairs: Maintenance crews can see the exact nature of an issue and address the most urgent problems first.

- Reduce Downtime: A clear visual of damage ensures that the right parts are ordered in advance, preventing unnecessary delays.

- Improve First-Time Fix Rates: Technicians arrive prepared with the necessary tools and knowledge, reducing repeat visits for the same problem.

By combining visual evidence with traditional inspection reports, repairs become more efficient, and vehicles spend more time on the road rather than in the shop.

The Power of Combining Visual

Inspections with ELD Data

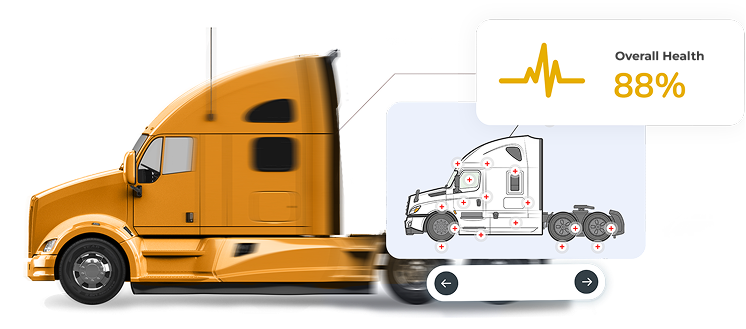

While an ELD provides valuable insights into a vehicle’s engine and electronic systems, a comprehensive equipment maintenance strategy should integrate both digital monitoring and manual inspections.

- Real-time engine performance monitoring (ELD)

- External mechanical condition assessment (visual inspection)

- Detailed documentation for maintenance teams (photo & video records)

This holistic approach reduces failures, increases compliance, and enhances overall fleet efficiency.

Making It Easier For Operators To Comply

Many companies turn to ELDs because they feel that they can not rely on their operators to consistently and diligently provide the data they need to ensure equipment safety and reliability. Driveroo addresses this challenge with several critical capabilities that overcome the obstacles that cause frustration and delay for operators when performing visual inspections.

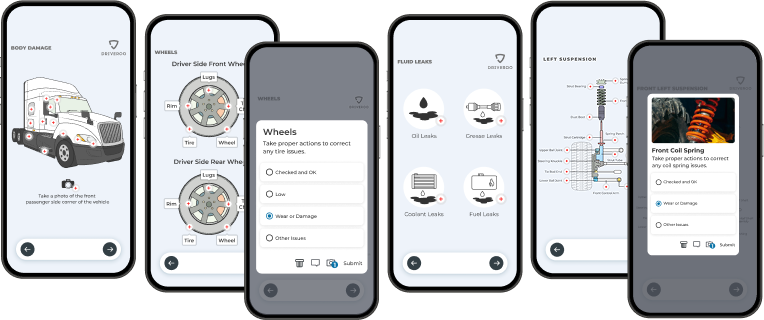

- Visuals, Not Forms: Driveroo offers a unique visual interface on the mobile app that shows operators exactly what to inspect using images of the actual equipment, making it easier for new employees to come up to speed.

- Built-in Short Cuts: Visual images are enhanced with a variety of time-saving capabilities like single tap, group tap and swipe to group which all shorten inspection time.

- Inspections That Remember: Driveroo inspections can remember prior issues and can contain a history of issues which eliminates repetition and delivers valuable information to the operator on the spot.

- Automated Data Collection: No more illegible notes, all inspection details are automatically captured and immediately available online. Camera, video and voice to text make it easier and faster for operators as well.

Driveroo is specifically designed for nontechnical users to be easier, faster and more intuitive, which leads to more consistent use and accountability.

Conclusion

ELDs are a game-changer for tracking vehicle performance, but they do not replace the need for hands-on inspections. Many important points of inspection and critical issues can only be identified through a proper walkaround.

By ensuring and helping operators efficiently perform thorough visual inspections, documenting defects with photos and videos, and integrating findings with ELD data, fleets can achieve maximum equipment uptime, safety, and compliance.